With more than 140 years’ experience in jet ejector technology, Körting Hannover AG can offer highly efficient and proven solutions for the shipbuilding industry.

Custom-designed jet ejectors are produced and tested in the main plant in Hanover, Germany

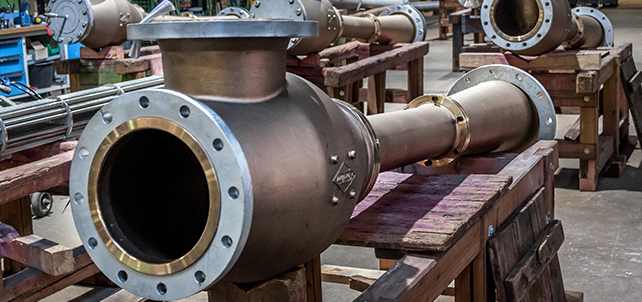

COSCO Dalian Shipyard Co. Ltd. appointed Körting Hannover AG to produce jet ejectors to nominal widths of DN 300 which are used for bilge and ballast systems. A new generation of the existing product range was required and jet ejectors with suction power of more than 500 m3/h had to be developed and manufactured. “What made the project so special was that we managed to comply with and implement the customers’ special demands in a short space of time. Something other competitors couldn’t manage to do”, explains Markus Kampers, project engineer at Körting Hannover AG. The first consignment has already been delivered to the customer. The second is to follow in January 2015.

Painstaking development

Testing capacities were quickly expanded to check the performance of the jet ejectors. Because it was vital to supply the quantity that streams through the jet ejector and measure it very precisely. On site, Körting Hannover AG had a total volume of 250 m3 of water which is circulated about three times per hour. As a result, a performance record for the Germanischer Lloyd (GL) classification society was provided directly in the main plant in Hanover, Germany. Internationally Körting is now the only company whose jet ejectors are fully GL-certified up to nominal widths of DN 300. “According to current GL regulations, any company manufacturing a jet ejector like this must be able to produce an equivalent performance record in their own plant”, explains Kampers when outlining one of the many benefits Körting offers.

Körting Venturi scrubber at work

Customised design

As the leading and at the same time oldest supplier of jet ejector technology, Körting delivers tailor-made solutions to its customers. All jet ejectors are custom-made to performance specifications. “Cavitation-free operation, minimal energy consumption and maximum suction power are the results of our tailor-made design”, reports Kampers. The jet ejectors in nominal widths of DN 300 for COSCO Dalian are made of high-quality, fully seawater-resistant cast bronze. “This allows us to achieve low weight, but extreme strength. What’s more the jet ejectors are very hard-wearing”. They have no electrical or mechanical drives, dynamic seals or moving parts. Therefore, jet ejectors stand apart because they have perfect dry-running capabilities, don’t get dirty easily and are consequently virtually maintenance-free. “The project for COSCO Dalian shows that Körting is fully capable of reacting to any conceivable enquiry from a customer thanks to its experience, flexibility and highly professional approach”, says Kampers.