Costs and competitive constraints for the company have led to new challenges in process technology. This requires new developments. However, even in the future the application of time and tested technologies can be a good payoff. One interesting example for this is the Venturi scrubber developed by Körting Hannover AG for the dedusting of industrial waste gases.

"New and on-going further developments of existing processes and procedures in environmental technology form a focal point for operators and manufacturers”, as Arnd Rötz, one of Körting Hannover AG’s graduated engineers and Head of the Waste Gas Cleaning Dept., explained. However, in many areas it has been shown that time and tested technologies can also be applied with great success. In this respect especially, the application of apparatus for the dedusting of waste gases must be considered. This process can take place – depending on requirements and marginal conditions – with wet-working or dry systems.

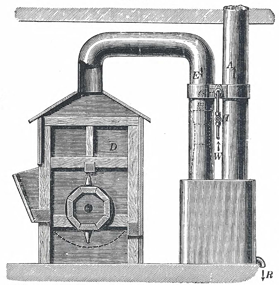

The particle size distribution of a dust requiring separation is the initial limitation in the choosing of a suitable dust separating system”, as Arnd Rötz reports. Whether a wet-working or a dry system should be applied is determined by the particular characteristics of the dust in question. A wet-working system would be applied in the case of characteristics such as, for example, “hygroscopic”, “water soluble”, “tends towards solid deposits” or “sticky”. With regard to wet systems, small dust particle sizes favour the Venturi scrubber. Körting Hannover AG manufactured its first Venturi scrubber as early as 1885. Today, this reliable technology is utilised successfully in many processes. “Körting Venturi scrubbers are designed and manufactured customer-specific for rated flows of approx. 300 up to 150.000 m³/h with pressure consumptions of 20 up to 150 mbar in all established materials”, as Arnd Rötz explained.

Above all, gas cleaning with Venturi scrubbers provides an optimal solution when the boundary conditions of the process, the local situation or the question of the material to be utilised place particular demands. An industrial scale test facility was built on the Körting premises in Hannover to ensure an on-going further development of this technology. “For example, fine dusts formed in flue gases when burning pulverised fuels are separated in a Venturi scrubber” as Arnd Rötz explained. “Variations with regard to ignition, combustion and emission characteristics of the utilised fuels as well as the energy required for the separation process in the Venturi scrubber can be investigated here.”

Burner trials for customers as well as the further development and optimisation of our own burner- and gas cleaning technology can be conducted at the new test facility. Newest surveys carried out by Körting have now shown that considerable improvements can still be achieved. In the case of new plans/designs for which pilot plants cannot be applied, the extensive knowledge and experiences of plant manufacturers gained in diverse application fields are indispensable,e.g. for a first estimation of the required energy consumption. As a competent contact partner Körting Hannover AG is always on hand to provide assistance.