Ideal for plants with highly polluted waste water

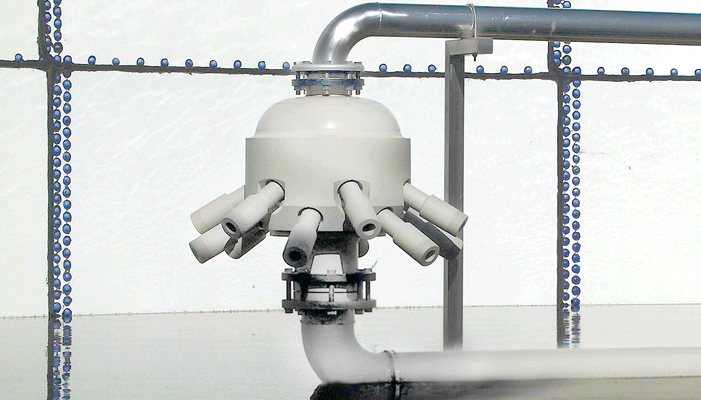

In its construction form the ejector for the aeration process corresponds to that of a jet ejector. Because organically polluted wastewater requires a high amount of oxygen and also because of the increasing height of modern biological waste water cleaning plants it is energetically more efficient to pre-compress the air mechanically to the hydrostatic pressure prevailing at the installation point of the ejector and to supply it so to the suction connection.

This waiving of an appreciable pressure in the ejector reduces the necessary motive pressure. At the same time, more favourable mixing ratios (suction flow : motive flow) are achieved. Motive nozzles of our ejectors are equipped with a non-clogging spiral. So the motive jet disperses the air already at a low motive pressure in a myriad of fine bubbles which are then mixed vigorously together with the motive flow in the mixing zone. This air/water mixture is injected into the aeration tank with a high turbulence. In this way the ejector guarantees optimum oxygen supply and a total intermixing of the tank contents. Even with a high biomass concentration in the waste water it is still possible to attain flow velocities which prevent deposits on the tank floor.

This air/water mixture is injected into the aeration tank with a high turbulence. In this way the ejector guarantees optimum oxygen supply and a total intermixing of the tank contents. Even with a high biomass concentration in the waste water it is still possible to attain flow velocities which prevent deposits on the tank floor.

FURTHER INFORMATION

Learn more about: Liquid jet gas compressor

Advantages of ejectors for waste water aeration

- maintenance-free - no moving elements

- high oxygen efficiency - Fine bubbles create large contact surfaces between air and water and high turbulence renews these contact surfaces.

- no deposits - The intensive jet flow directed towards the tank floor prevents deposits of biomass.

- straightforward control of oxygen supply

- non-clogging construction - The nozzle diameter defines the narrowest flow cross-section.

- no sealing problems - When the plant is inactive, water can enter the air pipeline without negative effects and when re-started, the ejector’s entraining effect expels any liquid in the pipe.

- design acc. to requirements - Various sizes can be designed and adapted to requirements.

DOWNLOAD

DOWNLOAD BROCHURE

ENQUIRY QUESTIONNAIRE